DIP Lines: 15

Annual Output: 28 million pcs

DIP Lines: 11

Annual Output: 32 million pcs

DIP Lines: 13

Annual Output: 35 million pcs

DIP Lines: 13

Annual Output: 46 million pcs

DIP Lines: 6

Annual Output: 15 million pcs

DIP Lines: 4

Annual Output: 6 million pcs

-

Automated Testing

Automated Testing -

Automated FCT

Automated FCT -

AGV

AGV -

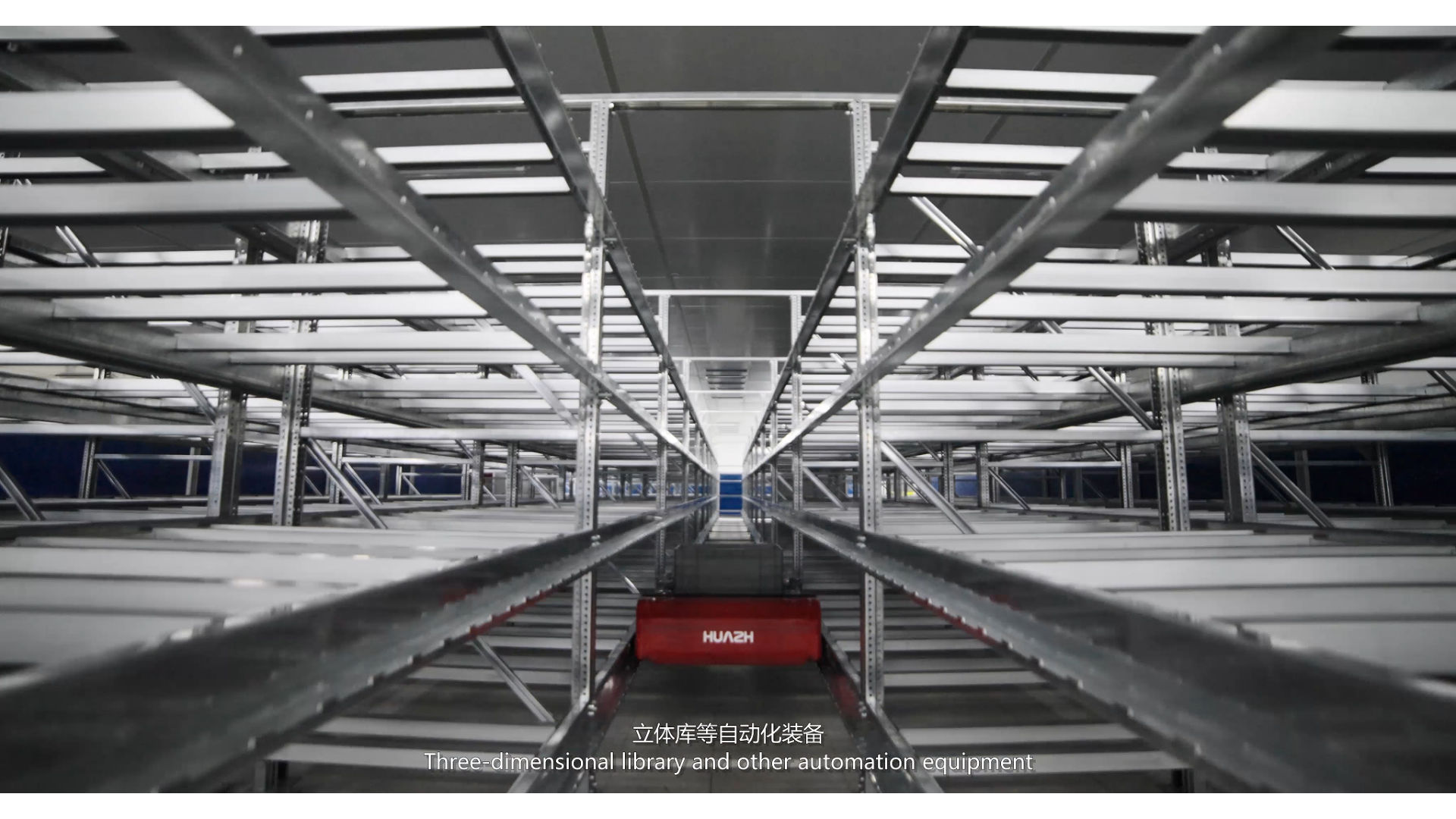

Automated High-Density Warehouse

Automated High-Density Warehouse

-

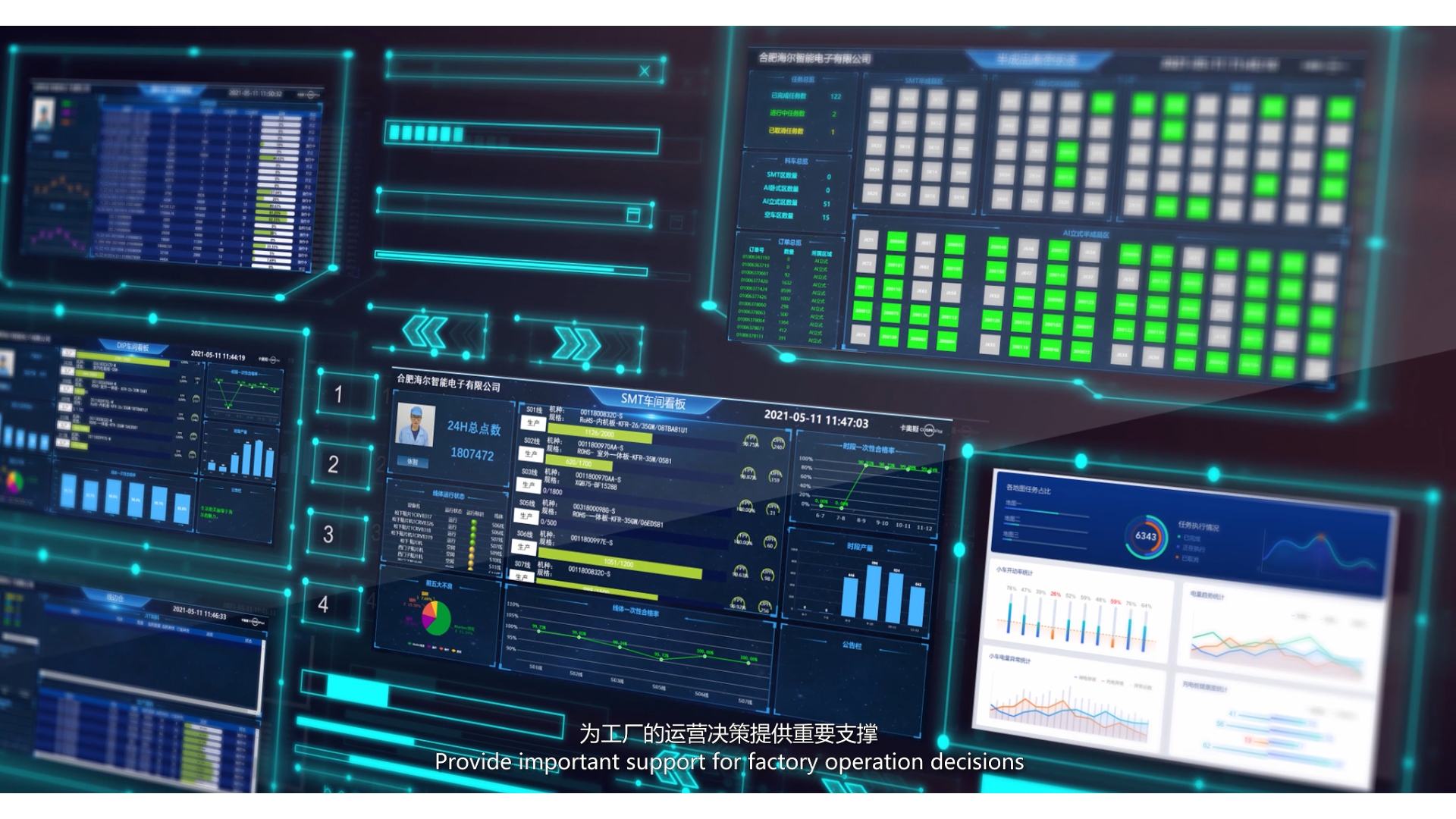

MES Management

MES Management -

Data Centers

Data Centers -

Order Management

Order Management -

Intelligent Decision-Making

Intelligent Decision-Making

-

AI-Powered Security

AI-Powered Security -

IE Engineering

IE Engineering -

AI Vision Inspection

AI Vision Inspection -

AI Agent

AI Agent

Manufacturing Capabilities:

SMT: Fully equipped with world-class placement machines (Panasonic, Fuji), meeting stringent production requirements.

DIP: Industry-leading automated production lines with capabilities including automatic insertion, testing, coating/potting, and packaging.

Digital and Intelligent Manufacturing:

The factories are committed to continuous upgrades in automation, digitalization, and AI-enabled, leveraging technologies from the third and fourth industrial revolutions.

In terms of automation, the factories implemented scenarios such as automatic material inflow and outflow, complex component insertion, automated testing, and smart logistics. In terms of digitalization, the self-developed systems for order fulfillment, environmental monitoring, process management, and intelligent decision-making enabling end-to-end data control across the value chain. In terms of AI-enabled, the factories actively applying AI technologies in areas such as security, virtual IE engineers, machine self-interaction, and computer vision. In addition, self-developed platforms such as collaborative manufacturing, electronic manufacturing systems, and full-scenario smart logistics have been recognized as national intelligent manufacturing demonstration scenarios.