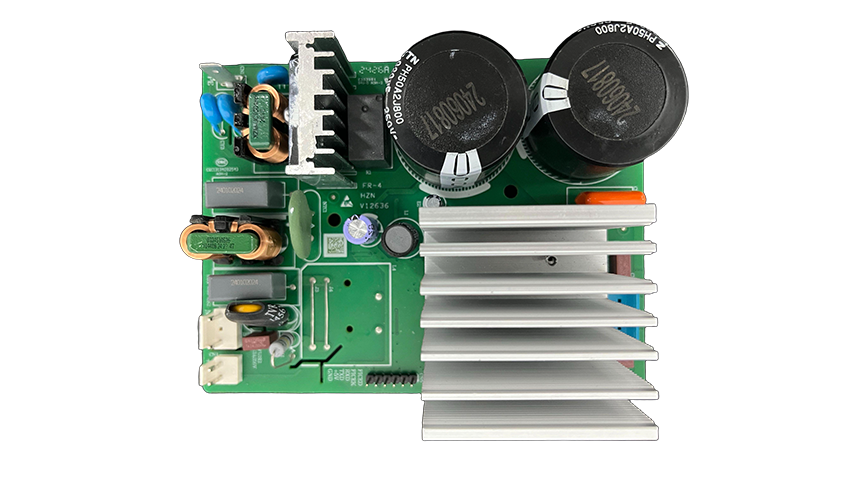

Voltage-Adaptive Inverter Board for Refrigerators

This refrigerator controller is primarily used in compressor control scenarios and is compatible with various mid-to-high-end refrigerator across different product categories.

Product Advantages

Compact size and high integration with significantly reduced overall dimensions; modular design with high EMC margin.

Maximum torque-per-amp ratio, space vector modulation, and overshoot control reduce switching losses, improving efficiency by 2%.

Field weakening control technology enables higher motor operating speeds.

Torque compensation reduces noise and vibration by over 90%, with harmonic reduction also exceeding 90%, ensuring stable and efficient low-frequency compressor operation.

Undervoltage frequency reduction and deceleration shutdown strategies reduce compressor wear and extend lifespan.

Nanosecond-level overcurrent protection, under/over-voltage protection, and overcurrent/overpower protection. Fault protection logic safeguards both drive circuitry and compressor, ensuring extremely low failure rates and low PPM.

Technical parameters

Parameter Item

Parameter

Input Voltage

110/220V adaptive

Input Power

Rated 400W, Peak 450W

Speed Control

PWM electronic or mechanical (optional)

Speed Range

1200–4500 rpm

Dimensions

133*100*45

Installation

Separate control box, independent from compressor