Industrial Fan Control Breakthrough! High-Frequency Injection + Composite Braking Achieves 100% Reverse Wind Start Success Rate

Industrial fan start-stop control has long faced challenges such as wind resistance disturbances and inertia shocks. Traditional solutions relying on mechanical braking or single electronic control strategies suffer from high state misjudgment rates and significant DC bus overvoltage risks.

COSMOPlat AIoT industrial fan controller innovatively integrates high-frequency injection detection and composite braking technology, enabling millisecond-level state recognition and flexible braking in forward and reverse wind scenarios. This breakthrough achieves 100% start success rate and precise bus voltage fluctuation control.

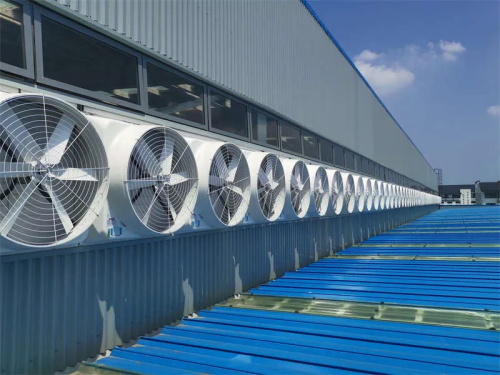

Field data shows: 42% energy reduction, 57% shorter reverse wind start time. The solution has already been successfully applied in demanding scenarios such as livestock farming and factory ventilation, redefining the standard for efficient, reliable, and adaptive fan control.

Three-Phase 3KW Fan Controller

I. Core Technological Breakthroughs Redefining Fan Control Standards

01

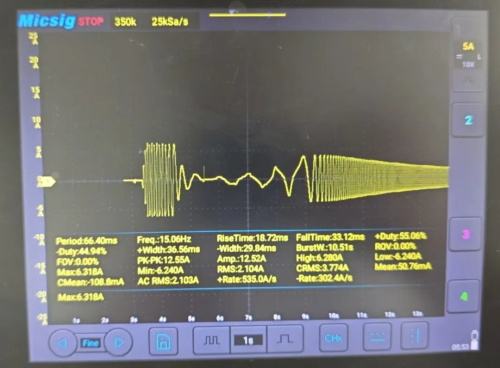

High-Frequency Injection Technology: Precisely Capturing Rotor Initial State

The COSMOPlat AIoT industrial fan controller adopts innovative high-frequency injection technology. By injecting a high-frequency voltage signal into the stator and analysing the resulting current response, the rotor pole position can be accurately detected. Compared with traditional back-EMF detection, this method offers three advantages:

Positioning Accuracy: Precisely identifies the start angle even when the motor is not fully stationary.

Dynamic Response: Refreshes position 1000 times per second during rotor inertia rotation, overcoming wind resistance interference.

Noise Immunity: Built-in harmonic separation algorithm eliminates inverter and high-power equipment interference.

Waveform of Reverse Wind Start-up

This breakthrough ensures 100% start success rate across forward wind, reverse wind, and standstill conditions, eliminating failures caused by misjudgments in traditional methods.

02

Composite Braking Technology: Balancing Efficiency and Safety

The COSMOPlat AIoT industrial fan controller provides two-tier braking strategies for different scenarios:

Low-Side Short-Circuit Braking: Ideal for small/medium fans requiring emergency stop. Simultaneously turns on inverter low-side power devices to dissipate kinetic energy quickly, limiting DC bus voltage fluctuations within 20%.

Reverse Current Closed-Loop Braking: Designed for large-inertia blades (e.g., centrifugal fans >2m). Injects reverse d-axis current to build electromagnetic braking torque, achieving soft deceleration and reducing surge current by 60%.

This combination ensures braking smoothness while reducing current shocks, offering dual guarantees for safe and stable fan operation.

Full-Scenario Adaptive Algorithm for Complex Conditions

The COSMOPlat AIoT industrial fan controller integrates a Dynamic Parameter Matching Engine and Fault-Tolerant Protection Mechanism:

Leverages a motor parameter library with 20+ features (inductance, back-EMF constants, etc.) to auto-generate optimal braking curves.

Detects DC bus overvoltage risks and switches braking modes in real time, preventing IGBT failures.

This design enables intelligent adaptation to diverse operating conditions, maintaining efficient and stable performance even in harsh environments.

II. Real-World Data: Immediate and Measurable Impact

01

Typical Scenario Performance

02

Industry Application Performance

Central AC Outdoor Units: Achieved 100% reverse wind start in -25°C, with 30% reverse wind load.

Livestock Farms: In humid, dusty environments with reverse wind speeds of 7m/s, start time reduced from 6s to 2.8s, energy consumption reduced by 38%.

Factory Ventilation Systems: For 3.2m fiberglass blades, peak DC bus voltage controlled below 650V (nominal 540V system), reducing overvoltage failure rate from 1.2/month to zero.

The COSMOPlat AIoT industrial fan controller will soon feature AI predictive braking algorithms that use historical operation data to forecast wind direction trends, further shortening braking response time. Combined with next-generation SiC (Silicon Carbide) power devices, overall fan system efficiency is expected to exceed 98%.

COSMOPlat AIoT

COSMOPlat AIoT is an industry-leading provider of intelligent control solutions, with business spanning hardware, software, data, and services. The company operates five global R&D centers and six major production bases. It holds an industry-leading position in technologies such as embedded operating systems, AI intelligent control, and interactive sensing. Currently, COSMOPlat AIoT offers over 1,000 product solutions, with an annual production capacity exceeding 180 million intelligent controllers.