AI Empowerment! COSMOPlat AIoT Recognized by WEF as One of the World’s First “Talent Spotlight” Enterprises

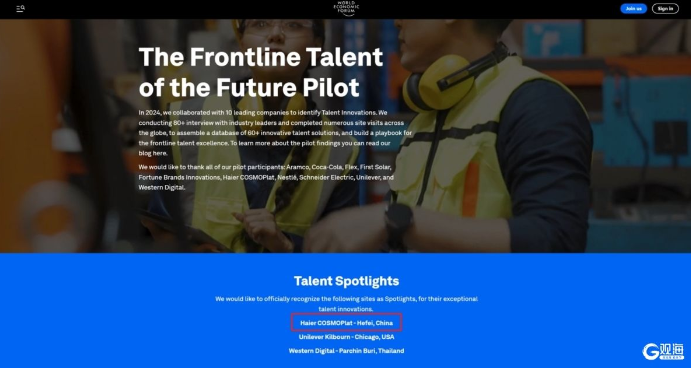

On the 12th, the World Economic Forum (WEF) published a white paper on its official website titled “Putting Talent at the Centre: An Evolving Imperative for Manufacturing,” announcing the latest results from its Future Frontline Talent pilot program.

Following in-depth interviews with dozens of industry leaders and on-site assessments, the expert panel selected the world’s first cohort of only three “Talent Spotlight” enterprises among advanced global manufacturers. COSMOPlat AIoT’s Hefei Interconnected Factory was the only Chinese enterprise to make the list. This marks another global recognition for COSMOPlat, following its award as the first “Lighthouse” in China’s intelligent controller industry in 2023, this time highlighting innovation in talent management and development empowered by AI.

White Paper Perspective: Talent as Investment, Not Cost

The white paper emphasizes that for enterprises to achieve holistic transformation, frontline talent should be treated as an investment rather than a cost. By developing customized talent strategies aligned with business needs, companies can drive innovation in talent cultivation and management models, improve production efficiency and workforce stability, and shape a human-centric path for manufacturing talent transformation.

Facing challenges in talent management, workforce development, and flexible employment needs such as “Mom Shifts,” COSMOPlat Hefei Interconnected Factory has combined technological innovation (AI, data analytics, image recognition) with management innovation (compensation systems, corporate culture) to achieve significant improvements in workforce-job matching, production efficiency, and employee satisfaction.

On one hand, leveraging artificial intelligence, advanced analytics, and image recognition, COSMOPlat developed the “Virtual IE Engineer.” This system integrates intelligent job assignment and automated ESOP (Electronic Standard Operating Procedure) generation. By considering product type, employee count, and skill levels, it generates customized work instructions and allocates tasks through AI algorithms. The ESOP preparation time has been reduced from 2–3 hours to under 3 seconds, increasing production line balance from 65% to 85%. At the same time, more “mom shift” employees have been enabled to participate flexibly in work, demonstrating AI's broader social value.

On the other hand, the company has built an internal innovation social platform, where frontline employees can share ideas and receive financial rewards. This has significantly fostered an innovation-driven culture, generating over 500 ideas in the past year and saving more than USD 1 million in costs. In payroll management, a digitalized system has replaced manual, paper-based processes, introducing transparent wage calculations and further improving employee satisfaction.

Through the application of large industrial AI models and other intelligent technologies, COSMOPlat continues to advance the synergistic development of industrial intelligence, machine intelligence, and frontline talent. To date, the COSMOPlat Tianzhi Industrial Large Model has been deployed across nine major industries including chemicals and molds, delivering 45 high-value scenario-based solutions. These solutions not only drive quality improvement and efficiency gains for enterprises but also create better working conditions and personal development opportunities for employees, enhancing workforce digital capabilities.

In the future, COSMOPlat will continue exploring breakthroughs in human-machine collaboration and industrial intelligence, promoting the deep integration of AI with industrial scenarios. Together with highly skilled talent, COSMOPlat is committed to co-creating a new future of high-quality and sustainable manufacturing development.

(By Yang Guang)

Source: Qingdao Daily / GuanHai News